Research

Indestructible

NDT tests: VT, MT, PT, UT, RT

Research

Non-destructive

defective welds and the location of discontinuities.

Research

Non-destructive

stable operation of industrial installations and

welded structures.

Kim Test

I guarantee

applicable standards.

Kim Test

Ensure

punctuality and availability.

Non-destructive testing

Services

Bet on experience

Our

Offer

VT - research

visual

detection and evaluation of external quality characteristics of a product using the human eye. Thanks to this method, it is possible to verify the surface indications of deviations from dimensions and the quality of the treated surface.

MT - research

magnetic - powder

the use of a magnetic field and detection means to locate in ferromagnetic materials discontinuities on the test surface or lying at a depth of up to about 2 mm.

PT - research

penetrative

most

universal type

surface research serving

for detecting discontinuities

material open in

the direction of the surface.

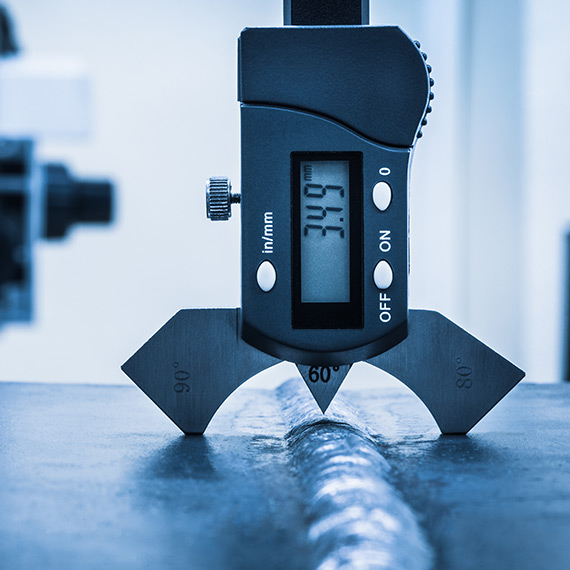

UT - research

ultrasonic

allowing to detect internal flat, spatial discontinuities located at a specific angle to the surface of the head travel. Ultrasonic waves are used for the test.

RT - research

radiographic

the most universal method of detecting internal discontinuities in all types of materials using X-ray or gamma radiation.

24/7 UTT - ultrasonic

thickness measurements

with the help of this

methods, we can determine the differences in the thickness of the material from which

the object is built, and so is his

cavities and corrosive wear.

Analysis and testing of the chemical composition of metals (PMI)

XRF spectrometer

enables a precise analysis of the alloy composition<metal structures where sampling is not possible.

Supervision

Welding (IWI)

We conduct welding supervision by certified IWI engineers according to the requirements of standards for quality assurance in welding EN ISO 3834, PN EN 1090.